New Holland has updated its FR forager, so what’s it like to drive? Last summer we didn’t need asking twice to climb aboard the titillated and refreshed Cruiser.

KEEPING IT BRIEF

- The FR gets a freshened-up design and lots of detailed improvements in the cab.

- A sensor in the chute measures the amount of crop flowing through it in order to detect a blockage.

- The pick-up is powered by belts instead of chains.

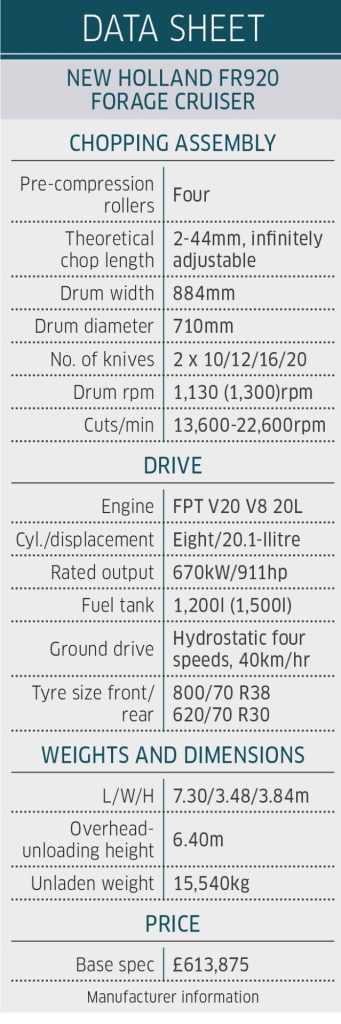

First things first, the New Holland Zedelgem engineering team hasn’t made any changes to the chassis or chopping unit on the FR forager. But what has changed on the five-model range is the ‘Natural Flow’ styling that was first introduced on the brand’s CR11 combines. Rather more relevant for the operator are the various detailed changes aimed at improving driving comfort.

More CANbus

While the engine (670kW/911hp in the top model, the featured Cruiser FR920) and the drivetrain remain untouched compared to the outgoing models, New Holland has gone one step farther in terms of data: instead of two CANbus lines, a total of four CANbus lines on the new range guarantee a high performance in this area.

This “LIN bus” communication line (use of LIN actuators) offers a glimpse into the future. Similar to combine harvesters and tractors that already have the PLM Intelligence system, this provides the cornerstone for further automation and smart solutions on the FRs. On the old machines, a large part of the CANbus network was already being used by electronic demanding features such as the steering system, IntelliFill lll filling camera, NutriSense NIR sensor and all other sensor information systems.

Looking at the tail end, the engine cooling pack now has adjustable fan blades that automatically adjust depending on engine load and temperature, which, in turn, saves up to 2.5% fuel, according to New Holland. A compressed air kit is also available from the factory that automatically blows out certain areas of the engine compartment at adjustable intervals.

Extra space

Most of the updates can be found in and around the cab, which now goes by the name of ‘ForageSuite’. Although the basic frame is identical to the previous generation, the interior has been significantly revised. The headlining has been raised, the rear wall of the cab slimmed down and the floor levelled to create more room for long legs. The storage compartments and the cool box have also been modified. Overall, interior volume of the cab has increased by 12%.

In addition, the noise insulation has been improved, for instance with special acoustic glass, so that, again according to the firm, a significant 2dB(A) less sound reaches the driver’s ear.

The design of the joystick hasn’t changed, but it and the buttons are easier to use. You can choose between three core packages: ‘Professional’, ‘Elite’ and ‘Standard’. These packs differ in their level of cab interior, for example, bringing leather clad elements and seat versions with ventilation.

The cab terminal has also been adapted to match the increased data stream. The larger Intelliview 4+ monitor has a 12.1-inch screen; there’s more computing power; improved menu navigation is now standard on the foragers; and a second monitor is available as an option. Although the new steering valve with the ‘custom steering’ option is located outside the cab, it is possible to alter the number of steering wheel revolutions to go from lock to lock on the terminal.

Chute under watch

If you look closely, you will see an additional box on the underside of the chute, which incidentally swivels through 210°. This is where the ‘CropSpeed’ system is housed — a radar sensor that records the speed of the crop flow for the first time. If the crop flow falls below 35km/hr, the FR’s operator is prompted with a warning on the screen. If the flow rate drops below 6km/hr, the pick-up is automatically switched off. Should the machine still manage to get bunged up, the operator can open large flaps on the chute to clear the blockage. The CropSpeed sensor costs £908 extra.

The IntelliFill III infrared camera unit is now equipped with its own Epec controller and is said to achieve good results when opening a field thanks to having more computing power to make it more responsive. This also eliminates having to manually change over from regular side filling to filling a trailer following behind.

Another detail on the crop flow system is the fact that the feed rollers will be offered with an optional hydraulic damping system in the future, and that the smooth roller will be fitted with a new and fully hardened scraper. Another longer service life item being added to the options list is a hardened shearbar from Busatis.

Further details

- The driver’s seat now has an integrated cooling function, and operators can rest their feet on ‘Harley bars’.

- There is a light sensor and access lighting system with a coming-home function.

- The harvester’s headlights, which are now LED as standard, can be dimmed individually.

- NH’s PLM Connect is now called FieldOps (Operations), and the firm’s telemetry link “Connectivity Included” is standard.

- The wiper intervals can be individually set for each of the four wipers on the terminal.

- With NutriSense NIR, the company says it will be possible in future to analyse and display theoretical milk yield per tonne of chopped forage. The feature is based on the Milk 2006 model.

- The list price for the next generation of New Holland FR920 Forage Cruiser is just under £613,875. Cost of the headers is on top.

Summary

New Holland is now entering the next stage of developing its forage harvesters, with the changes providing the groundwork for developing further automation options.

For the here and now, the operator benefits from many welcome changes to the FR’s ‘ForageSuite’ cab. Although the hardware around the main drum has been tweaked, the harvester’s chopping unit, chassis and engine remain unchanged.

Lucas Colsman

For more up-to-date farming news click here and subscribe now to profi and save.