Abstract

Many technological breakthroughs in electronics and photonics were made possible by downscaling—the process of making elementary devices smaller in size1,2,3,4,5. The downsizing of light-emitting diodes (LEDs) based on III–V semiconductors led to micro-LEDs5,6,7,8,9,10,11,12, an ‘ultimate technology’ for displays. However, micro-LEDs are costly to produce and they exhibit severe efficiency losses when the pixel sizes are reduced to about 10 μm or less, hindering their potential in commercial applications. Here we show the downscaling of an emerging class of LEDs based on perovskite semiconductors to below the conventional size limits. Micro- and nano-perovskite LEDs (micro-PeLEDs/nano-PeLEDs) with characteristic pixel lengths from hundreds of micrometres down to about 90 nm are demonstrated, through a localized contact fabrication scheme that prevents non-radiative losses at the pixel boundaries. For our near-infrared (NIR) and green micro-PeLEDs, average external quantum efficiencies (EQEs) are maintained at around 20% across a wide range of pixel lengths (650 to 3.5 μm), exhibiting minimum performance reduction on downsizing. Our nano-PeLEDs with characteristic pixel lengths down to about 90 nm represent the smallest LEDs reported, enabling a record-high pixel density of 127,000 pixels per inch (PPI) among all classes of LED arrays. Our demonstration showcases the strength of micro- and nano-PeLEDs as a next-generation light-source technology with unprecedented compactness and scalability.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data supporting the findings of this study are available within the paper and its Supplementary Information.

References

Cao, W. et al. The future transistors. Nature 620, 501–515 (2023).

Lundstrom, M. S. & Alam, M. A. Moore’s law: the journey ahead. Science 378, 722–723 (2022).

Kim, T. I. et al. Injectable, cellular-scale optoelectronics with applications for wireless optogenetics. Science 340, 211–216 (2013).

Park, S. I. et al. Soft, stretchable, fully implantable miniaturized optoelectronic systems for wireless optogenetics. Nat. Biotechnol. 33, 1280–1286 (2015).

Behrman, K. & Kymissis, I. Micro light-emitting diodes. Nat. Electron. 5, 564–573 (2022).

Jin, S. X., Li, J., Li, J. Z., Lin, J. Y. & Jiang, H. X. GaN microdisk light emitting diodes. Appl. Phys. Lett. 76, 631–633 (2000).

Jiang, H. X., Jin, S. X., Li, J., Shakya, J. & Lin, J. Y. III-nitride blue microdisplays. Appl. Phys. Lett. 78, 1303–1305 (2001).

Huang, Y., Hsiang, E. L., Deng, M. Y. & Wu, S. T. Mini-LED, micro-LED and OLED displays: present status and future perspectives. Light Sci. Appl. 9, 105 (2020).

Shin, J. et al. Vertical full-colour micro-LEDs via 2D materials-based layer transfer. Nature 614, 81–87 (2023).

Amano, H., Kito, M., Hiramatsu, K. & Akasaki, I. p-type conduction in Mg-doped GaN treated with low-energy electron beam irradiation (LEEBI). Jpn. J. Appl. Phys. 28, L2112–L2114 (1989).

Nakamura, S., Mukai, T. & Senoh, M. Candela-class high-brightness InGaN/AlGaN double-heterostructure blue-light-emitting diodes. Appl. Phys. Lett. 64, 1687–1689 (1994).

Ponce, F. A. & Bour, D. P. Nitride-based semiconductors for blue and green light-emitting devices. Nature 386, 351–359 (1997).

Meng, W. et al. Three-dimensional monolithic micro-LED display driven by atomically thin transistor matrix. Nat. Nanotechnol. 16, 1231–1236 (2021).

Baek, W. et al. Ultra-low-current driven InGaN blue micro light-emitting diodes for electrically efficient and self-heating relaxed microdisplay. Nat. Commun. 14, 1386 (2023).

Meng, T. et al. Ultrahigh-resolution quantum-dot light-emitting diodes. Nat. Photon. 16, 297–303 (2022).

Zhao, J. et al. Large-area patterning of full-color quantum dot arrays beyond 1000 pixels per inch by selective electrophoretic deposition. Nat. Commun. 12, 4603 (2021).

Fan, J. & Qian, L. Quantum dot patterning by direct photolithography. Nat. Nanotechnol. 17, 906–907 (2022).

Liu, Z. et al. Micro-light-emitting diodes with quantum dots in display technology. Light Sci. Appl. 9, 83 (2020).

Deng, T. et al. Pixelated phosphor converter for laser-driven adaptive lighting. Laser Photonics Rev. 17, 2300240 (2023).

Park, J. et al. Electrically driven mid-submicrometre pixelation of InGaN micro-light-emitting diode displays for augmented-reality glasses. Nat. Photon. 15, 449–455 (2021).

Lu, B. et al. Dennard scaling in optoelectronics: scientific challenges and countermeasures of micro-LEDs for displays. Laser Photonics Rev. 16, 2100433 (2022).

Zhuang, Z., Iida, D. & Ohkawa, K. Investigation of InGaN-based red/green micro-light-emitting diodes. Opt. Lett. 46, 1912–1915 (2021).

Dussaigne, A. et al. Full InGaN red (625 nm) micro-LED (10 μm) demonstration on a relaxed pseudo-substrate. Appl. Phys. Express 14, 092011 (2021).

Sheen, M. et al. Highly efficient blue InGaN nanoscale light-emitting diodes. Nature 608, 56–61 (2022).

Liu, X. et al. N-polar InGaN nanowires: breaking the efficiency bottleneck of nano and micro LEDs. Photonics Res 10, 587–593 (2022).

Tan, Z.-K. et al. Bright light-emitting diodes based on organometal halide perovskite. Nat. Nanotechnol. 9, 687–692 (2014).

Cho, H. et al. Overcoming the electroluminescence efficiency limitations of perovskite light-emitting diodes. Science 350, 1222–1225 (2015).

Wang, N. et al. Perovskite light-emitting diodes based on solution-processed self-organized multiple quantum wells. Nat. Photon. 10, 699–704 (2016).

Yuan, M. et al. Perovskite energy funnels for efficient light-emitting diodes. Nat. Nanotechnol. 11, 872–877 (2016).

Liu, X. et al. Metal halide perovskites for light-emitting diodes. Nat. Mater. 20, 10–21 (2021).

Zhao, B. et al. High-efficiency perovskite–polymer bulk heterostructure light-emitting diodes. Nat. Photon. 12, 783–789 (2018).

Cao, Y. et al. Perovskite light-emitting diodes based on spontaneously formed submicrometre-scale structures. Nature 562, 249–253 (2018).

Lin, K. et al. Perovskite light-emitting diodes with external quantum efficiency exceeding 20 per cent. Nature 562, 245–248 (2018).

Chiba, T. et al. Anion-exchange red perovskite quantum dots with ammonium iodine salts for highly efficient light-emitting devices. Nat. Photon. 12, 681–687 (2018).

Sun, Y. et al. Bright and stable perovskite light-emitting diodes in the near-infrared range. Nature 615, 830–835 (2023).

Guo, B. et al. Ultrastable near-infrared perovskite light-emitting diodes. Nat. Photon. 16, 637–643 (2022).

Kim, J. et al. Ultra-bright, efficient and stable perovskite light-emitting diodes. Nature 611, 688–694 (2022).

Chen, W. et al. Highly bright and stable single-crystal perovskite light-emitting diodes. Nat. Photon. 17, 401–407 (2023).

Hsu, C. et al. Efficient mini/micro-perovskite light-emitting diodes. Cell Rep. Phys. Sci. 2, 100582 (2021).

Yang, X. et al. Towards micro-PeLED displays. Nat. Rev. Mater. 8, 341–353 (2023).

Liu, D. et al. Direct optical patterning of perovskite nanocrystals with ligand cross-linkers. Sci. Adv. 8, eabm8433 (2022).

Liu, D. et al. Nondestructive direct optical patterning of perovskite nanocrystals with carbene-based ligand cross-linkers. ACS Nano 18, 6896–6907 (2024).

Kim, M., Sadhukhan, P. & Myoung, J.-M. High-performance blue perovskite films and micro-arrays for light-emitting diodes with ionic liquid interlayer. Adv. Funct. Mater. 34, 2309436 (2023).

Jastrzebska-Perfect, P. et al. On-site growth of perovskite nanocrystal arrays for integrated nanodevices. Nat. Commun. 14, 3883 (2023).

Ren, A. et al. High-bandwidth perovskite photonic sources on silicon. Nat. Photon. 17, 798–805 (2023).

Bao, C. et al. Bidirectional optical signal transmission between two identical devices using perovskite diodes. Nat. Electron. 3, 156–164 (2020).

Xiong, J., Hsiang, E.-L., He, Z., Zhan, T. & Wu, S.-T. et al. Augmented reality and virtual reality displays: emerging technologies and future perspectives. Light Sci. Appl. 10, 216 (2021).

Kim, S. et al. Primary color generation from white organic light-emitting diodes using a cavity control layer for AR/VR applications. Org. Electron. 87, 105938 (2020).

Ding, S. et al. Phase dimensions resolving of efficient and stable perovskite light-emitting diodes at high brightness. Nat. Photon. 18, 363–370 (2024).

Ma, D. et al. Distribution control enables efficient reduced-dimensional perovskite LEDs. Nature 599, 594–598 (2021).

Acknowledgements

This work was supported by the National Key Research and Development Program of China (2022YFA1204800), the National Natural Science Foundation of China (NSFC) (62274144, 62005243), the Zhejiang Provincial Government, the Natural Science Foundation of Zhejiang Province (LR21F050003), Fundamental Research Funds for the Central Universities and Zhejiang University Education Foundation Global Partnership Fund. S.D.S. acknowledges support from the Royal Society and Tata Group (UF150033). K.J. acknowledges the Royal Society studentship. The authors acknowledge financial support from the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation programme (HYPERION, grant agreement number 756962). We are grateful to L. Feng and LinkZill Technology (Hangzhou) for the provision of the TFT array that powered the active-matrix micro-PeLED display. We thank W. Wang (Zhejiang University) for his assistance with FIB and SEM measurements and P. Xu and L. Yang (Zhejiang University) for helpful discussions. We thank L. Dai (Cambridge University) for his assistance with the hyperspectral microscopic experiments. We acknowledge the Center of Electron Microscopy, Zhejiang University, for their assistance with the TEM, FIB and EDX experiments. J. Sun of ZJU Micro-Nano Fabrication Center is acknowledged for his professional and enthusiastic technical assistance. We thank L. Xiao from the Instrumentation and Service Center for Molecular Sciences at Westlake University for the assistance with the FLIM measurements. The authors thank the Core Facilities, State Key Laboratory of Extreme Photonics and Instrumentation, Zhejiang University for technical support. We thank M. Yu, Y. Zhao and X. Yang for their administrative support.

Author information

Authors and Affiliations

Contributions

Y.L. planned the research and designed the experiments under the guidance of D.D. and B.Z. Y.L. fabricated the micro- and nano-PeLEDs with Y.W., Y. Yuan and Z.R. and carried out the device characterizations. Y.L. and Y.W. fabricated the NIR micro-PeLEDs and nano-PeLEDs. Y.L. and Y.W. carried out the optical microscopy, SEM and transient EL measurements. Y. Yuan and S.X. fabricated and characterized the green micro-PeLEDs. Y. Yuan carried out the operational stability measurements of the green micro-PeLEDs. Y.L. and Y. Yuan prepared the green active-matrix micro-PeLED display. Z.R. and Y.W. fabricated and measured the red micro- and nano-PeLEDs. W.T. fabricated the CsSnI3-based micro-PeLEDs. Z.L. contributed to the fabrication of the sky-blue micro-PeLEDs. K.J. performed the hyperspectral microscopy experiments under the supervision of S.D.S. B.Y. contributed to device analyses. Y. Yang carried out the TCSPC measurements. Y.G., S.Z., K.Z. and G.Z. contributed to experiments and analyses. Y.L., Y.W., Y. Yuan and Z.R. wrote the initial draft of the manuscript, which was revised by D.D. and B.Z. All authors contributed to the work and commented on the paper.

Corresponding authors

Ethics declarations

Competing interests

D.D., Y.L., B.Z. and Y.W. are inventors on CN patent application 202410198153.5. The other authors declare no competing interests.

Peer review

Peer review information

Nature thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

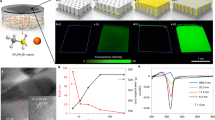

Extended Data Fig. 1 Substrates fabricated with and without using the localized contact method.

a,b, Schematics of devices fabricated without and with the localized contact method, respectively. For devices prepared using the localized contact method, an etched insulating layer is used to define the active area. The sky-blue arrows represent the direction of the current flow. c,d, Top-view SEM images of the pixel boundaries prepared without and with the localized contact method, respectively. e, Depth profiles of localized contact area by the profilometer. f, AFM images of the active areas prepared by the localized contact method.

Extended Data Fig. 2 Perovskites on the substrates fabricated with and without using the localized contact method.

a, AFM image of the active area with a characteristic length of 30 μm prepared by the localized contact method. b, Roughness of the localized contact area (region (i) in panel a). c, Roughness of the insulated area (region (ii) in panel a). d, SEM image of perovskite sample on substrate fabricated without using the localized contact method. e, SEM image of perovskite sample on substrate prepared by the localized contact method. f, Sidewall/pixel area ratio (%) as a function of characteristic length.

Extended Data Fig. 3 Morphological characteristics of perovskite samples on substrates prepared by the localized contact method.

a, Top-view SEM images of the active area of perovskite samples on substrates prepared by the localized contact method. The upper-right panel shows the SEM image of the perovskite deposited in the active pixel area. The bottom-right panel shows the SEM image of the perovskite deposited across the active pixel region and the insulating region. b,c, Distributions of perovskite grain sizes in the active pixel region and the insulating region, respectively.

Extended Data Fig. 4 SEM image and HAADF-STEM images of the perovskite samples on the substrates prepared by the localized contact method.

a, Top-view SEM image of the active area of the perovskite samples on substrates prepared by the localized contact method. HAADF-STEM images of the perovskite material deposited in the insulating area (b) and in the central region of the localized contact area (c).

Extended Data Fig. 5 PL and EL imaging of NIR perovskites on substrates fabricated with and without using the localized contact method.

a,b, FLIM images of NIR perovskite samples on substrates fabricated without and with the localized contact method, respectively. c, Time-resolved PL decay kinetics of the perovskite in different regions denoted in panels a and b. d,e, Fluorescence optical microscopic images of NIR micro-PeLEDs fabricated with (d) and without (e) the localized contact method with pixel lengths ranging from 200 μm to about 10 μm.

Extended Data Fig. 6 Further fluorescence measurements of NIR micro-PeLEDs fabricated with and without the localized contact method.

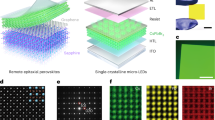

a, Normalized EL spectra of micro-PeLEDs using the localized contact method with pixel lengths ranging from 650 μm to about 10 μm at a radiance of 100 W sr−1 m−2. b, Time-resolved PL decay kinetics of perovskite samples on substrates using the localized contact method with various characteristic pixel lengths. Fluence: 5 nJ cm−2. c, EL mapping of the 100 × 100-μm2 area of a NIR micro-PeLED using the localized contact method. The measured region of 100 × 100 μm2 is in the centre of the micro-PeLED with a characteristic length of 200 μm. The scanning step interval is 1 μm. d, EL spectral information in the selected region in panel c along the X axis. e,f, Hyperspectral microscopy images of the micro-PeLEDs fabricated without (e) and with (f) the localized contact method.

Extended Data Fig. 7 Images of NIR and green nano-PeLED arrays fabricated using the localized contact method.

a, SEM images of the patterned pixel areas in nano-PeLEDs with characteristic pixel lengths of 890, 440 and 90 nm (from the same samples shown in Fig. 2g). b, Optical microscopic images of the patterned pixel areas in nano-PeLEDs with characteristic pixel lengths of 890, 440 and 90 nm. c, Optical microscopic images of working NIR nano-PeLED arrays with characteristic pixel lengths of 890, 440 and 90 nm. d, Optical microscopic images of working green nano-PeLED arrays with characteristic pixel lengths of 890, 440 and 90 nm.

Extended Data Fig. 8 Further measurements for PeLEDs fabricated using the localized contact method.

a–d, Optical microscope images of green micro-PeLED arrays with different pixel resolutions of 64 PPI (a), 635 PPI (b), 1,270 PPI (c) and 2,540 PPI (d). e, EL mapping of the 100 × 100-μm2 area of a green micro-PeLED using the localized contact method. The measured region of 100 × 100 μm2 is in the centre of the micro-PeLED with a characteristic length of 200 μm. The scanning step interval is 1 μm. f, EL spectral information of the PeLEDs in the boxed region of panel e. g,h, Maximum luminance versus characteristic pixel length for the green (g) and red (h) PeLEDs. i, Spectral stability of red micro-PeLEDs fabricated using the localized contact method. EL spectra are obtained from the centre of a red micro-PeLED with a characteristic length of 200 μm.

Extended Data Fig. 9 Spectral and efficiency data of red micro-PeLEDs/nano-PeLEDs.

a, One-dimensional EL spectral distribution in red micro-PeLEDs. b, EQE–luminance data. c, EQE versus characteristic pixel length plot for red micro-PeLEDs/nano-PeLEDs. The box plots and Gaussian fitting were generated from the EQE data, indicating the mean (empty squares), standard deviation, lower quartile (25%), median (50%), upper quartile (75%), interquartile range (25–75%) and maximum/minimum (crosses) of the data. The background colours cyan, light purple and pink denote length-scale regimes corresponding to mini-PeLEDs, micro-PeLEDs and nano-PeLEDs, respectively.

Extended Data Fig. 10 Efficiency and spectral data of sky-blue micro-PeLEDs.

a, EQE versus characteristic pixel length plot for sky-blue micro-PeLEDs. b, EL spectrum of a sky-blue micro-PeLED (peak wavelength: 488 nm). Inset shows the image of a working micro-PeLED array with a characteristic pixel length of 10 μm (driving voltage: 5.5 V).

Extended Data Fig. 11 Structure of the active-matrix micro-PeLED display.

The fabrication processes of the active-matrix micro-PeLED display are available in Methods. The TFT array was provided by LinkZill Technology (Hangzhou). IGZO denotes indium gallium zinc oxide.

Supplementary information

Supplementary Information

Supplementary Figures 1–14, Supplementary Tables 1–4 and Supplementary References

Supplementary Video 1

Video clip ‘Growing Tree’ played on the active-matrix micro-PeLED display

Supplementary Video 2

Video clip ‘Rotating Earth’ played on the active-matrix micro-PeLED display

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lian, Y., Wang, Y., Yuan, Y. et al. Downscaling micro- and nano-perovskite LEDs. Nature (2025). https://doi.org/10.1038/s41586-025-08685-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41586-025-08685-w